Manufacturing Execution System (MES)

AdoMES is a professional production management solution for factories developed by AdoERP

AdoMES is a solution that combines MES and ERP, helping businesses synchronize 100% of their operations on a single software platform.

What is MES?

The MES (Manufacturing Execution System) is a production operating system software designed to manage production processes, controlling and monitoring manufacturing activities in real time.

MES acts as a bridge between the Enterprise Resource Planning (ERP) system and the control and monitoring systems at the factory. MES helps optimize production processes, improve product quality, and enhance the operational efficiency of the factory.

What is AdoMES?

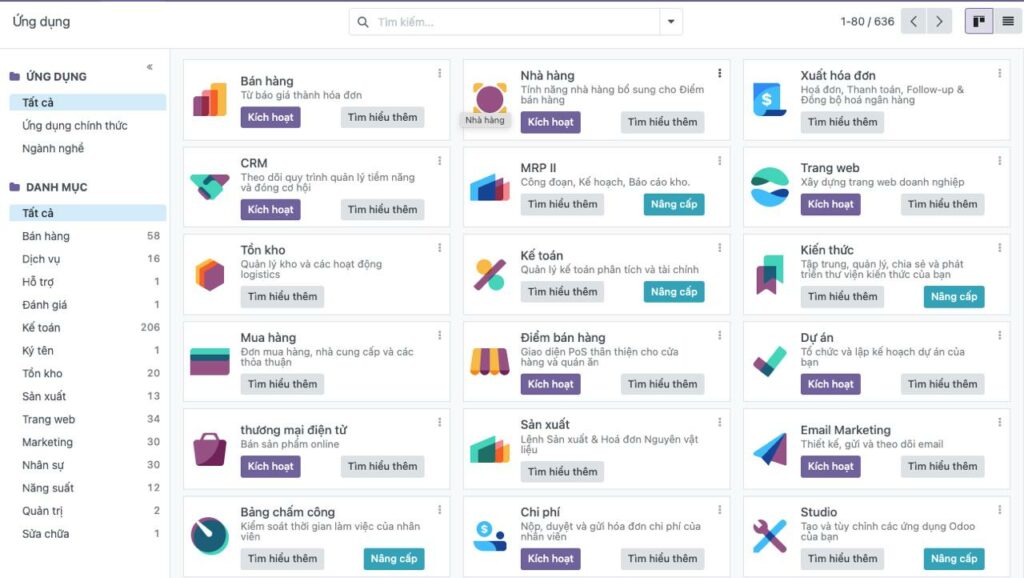

The production operating system integrated with Odoo ERP. The original Odoo software (version 17.0) still does not have an MES function, stopping at the MRP (Manufacturing Resources Planning) level, which is limited to material planning. The MRP function in Odoo allows for material deduction, inventory management, and efficient automated supply chain planning. However, Odoo MRP does not meet the requirements for planning and monitoring production activities in real time.

With experience in implementing custom MES solutions for many manufacturing plants across various industries, we have standardized and developed a powerful and flexible MES solution that meets the diverse and complex challenges of different types of factories. The MES function can be used alongside the MRP function in Odoo without any conflicts. However, once MES is implemented, there is no need to deploy MRP because MES is the next step in the development of MRP, encompassing all MRP functions but with more detailed and specific capabilities.

Enhance production efficiency with the Manufacturing Execution System (MES).

Integration and automation

AdoMES tightly integrates enterprise resource management with manufacturing execution management, helping to automate production processes from start to finish, thereby enhancing operational efficiency.

Automatically optimize the factory's machinery and equipment resources, calculate the best allocation, and assign work orders to each machine.

Real-time management

Provide real-time information about the production process, allowing managers and staff to have an overview and continuous updates on the production status, enabling quick and accurate decision-making.

Manage inventory at every stage of production, handle defective goods, and oversee the delivery and receipt of each process step.

Optimize production operations

AdoMES helps detect and minimize production issues, optimize the use of materials and labor, improve product quality, and reduce machine downtime.

AdoMES meets the requirements for both complex and simple production process planning and material standards.

Analysis and reporting

Provide powerful analytical tools that help businesses monitor performance, assess progress, and evaluate the effectiveness of each process, enabling timely adjustments to improve production efficiency.

Real-time dynamic reporting, allowing for multidimensional analysis.

Key benefits of using the AdoMES MES system include:

The AdoMES production management and operating system offers several practical benefits, such as:

Risk control

Proactively and flexibly plan production based on the resources available at the factory. Create detailed machine schedules for each machine and forecast production timelines, calculating completion times from the moment the plan is made.

Optimize production capacity

ERP production management software helps increase factory operational efficiency by easily identifying bottlenecks in resource allocation during operations and optimizing them.

Real-time visual reporting

Update production data and view real-time production reports and analyses, as each process step is accompanied by a guidance screen and real-time data updates.

Theoretical production cost

Once the BOM and production process are created, the system can calculate the theoretical production cost, allowing for a comparison with the actual production cost after the production order is executed.

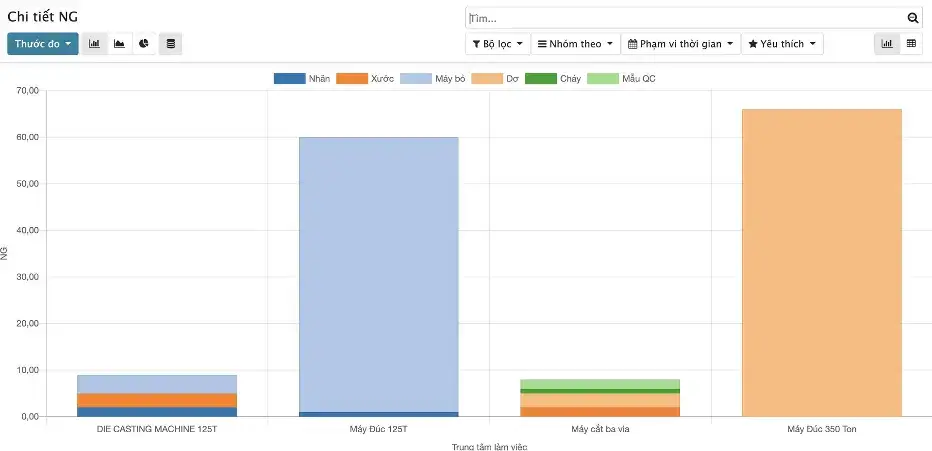

Reduce defective goods

Allow for error classification statistics, detailing each type of error by process, machine, operator, and time, corresponding to machine operating parameters. This enables operators to identify the root causes, implement corrective measures, prevent recurrence, and track improvement results over time.

Manage inventory at each production stage.

Manage raw materials, semi-finished products, and finished products at each stage, oversee material flow between stages, and handle defective goods at each step of the process.

Optimize the supply chain

Automatically propose material supply based on current inventory and future production/sales plans.

Actual production cost

Track the runtime of each machine in real-time, monitor material consumption and actual material costs, while also calculating labor costs per production stage based on output, thereby accurately calculating the actual production cost.

The main features of AdoERP MES include

The key features of the AdoERP MES production management software include:

MES Dashboard

MES Overall Production Planning

Automatically propose material supply in ERP

Overall work order for each stage in MES

Automatically calculate and forecast production resources

Machine work schedule

Step-by-step operation guidance for each stage

Update production progress

Production report

Inventory management at each stage of the process

Traceability

Manage scrap goods (NG)

Manage consumable materials

Calculate production cost

The main features of the AdoERP MES production management software.

The solution is a combination of the MES production operating system integrated within the Odoo ERP system. Therefore, MES operates synchronously with other functional modules of Odoo such as Purchasing, Logistics, Inventory, Accounting and Finance, Sales, Human Resources, Maintenance, Equipment, etc., all within the same system.

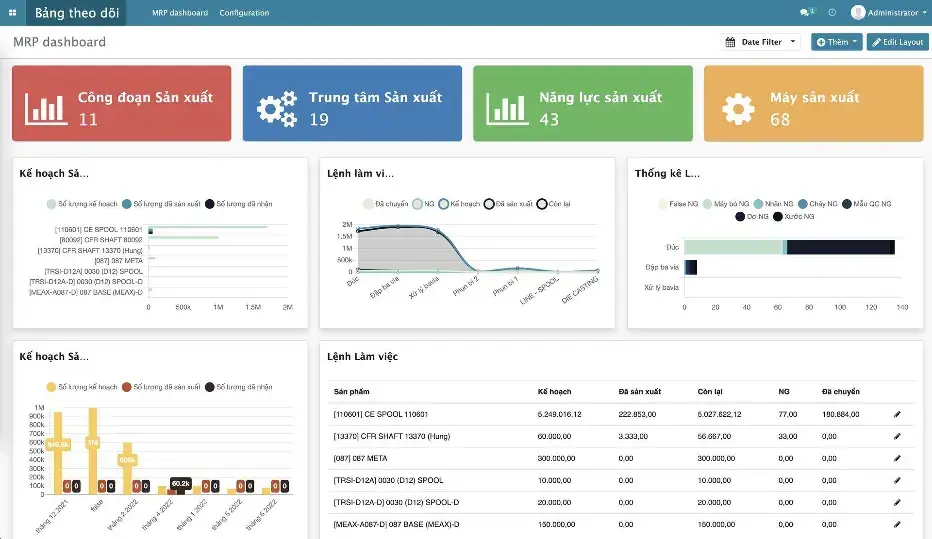

MES Dashboard

(The above image: OneMRP production management software dashboard)

The customizable dashboard can be set up according to the user, allowing for powerful permission management.

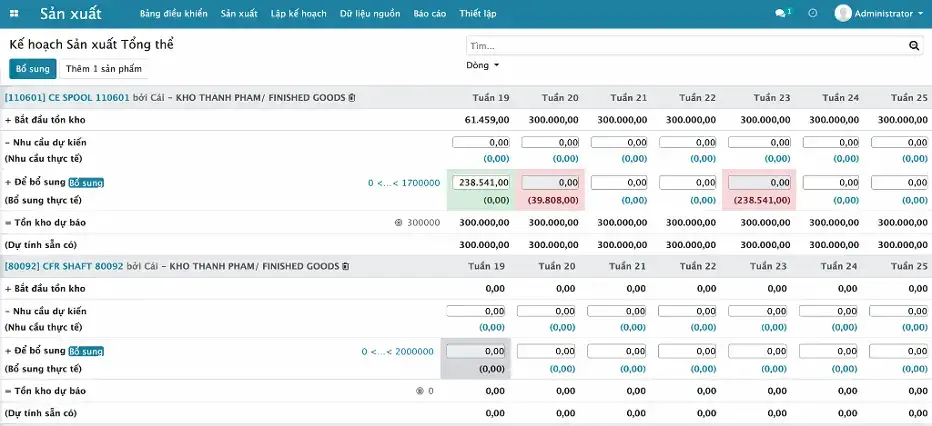

Overall MES Production Planning

(The above image: Overall production planning system)

Automatically calculate and forecast future inventory levels based on current stock, purchase and sales orders, and current production orders.

Automatically suggest replenishment (purchasing, production, or transferring stock from other locations) when inventory is insufficient, based on replenishment rules or minimum stock levels.

Automatically generate production orders or purchase orders (PO) based on supply rules.

Automatically propose material supply in ERP.

(Hình trên: Hệ thống đề xuất tự động cung ứng vật tư)

Based on the current inventory of materials, the procurement plan, the production plan, and sales forecasts, the system automatically calculates the future inventory of each product.

Based on the supply rules established for each product, the system can automatically generate production orders, purchase requests, or purchase orders to ensure the desired inventory levels.

The configurations are flexibly applied to each product.

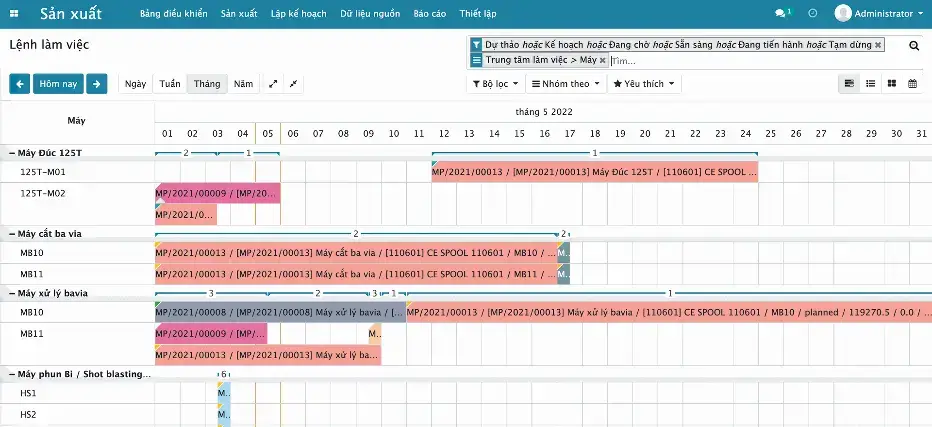

Overall work orders for each MES process stage.

(Hình trên: Phân bổ lệnh làm việc cụ thể chi tiết đến từng công đoạn)

Management can always view a visual and detailed production overview for each process stage in real-time. Production planners can simultaneously optimize multiple production plans based on priority or make adjustments using intuitive drag-and-drop actions.

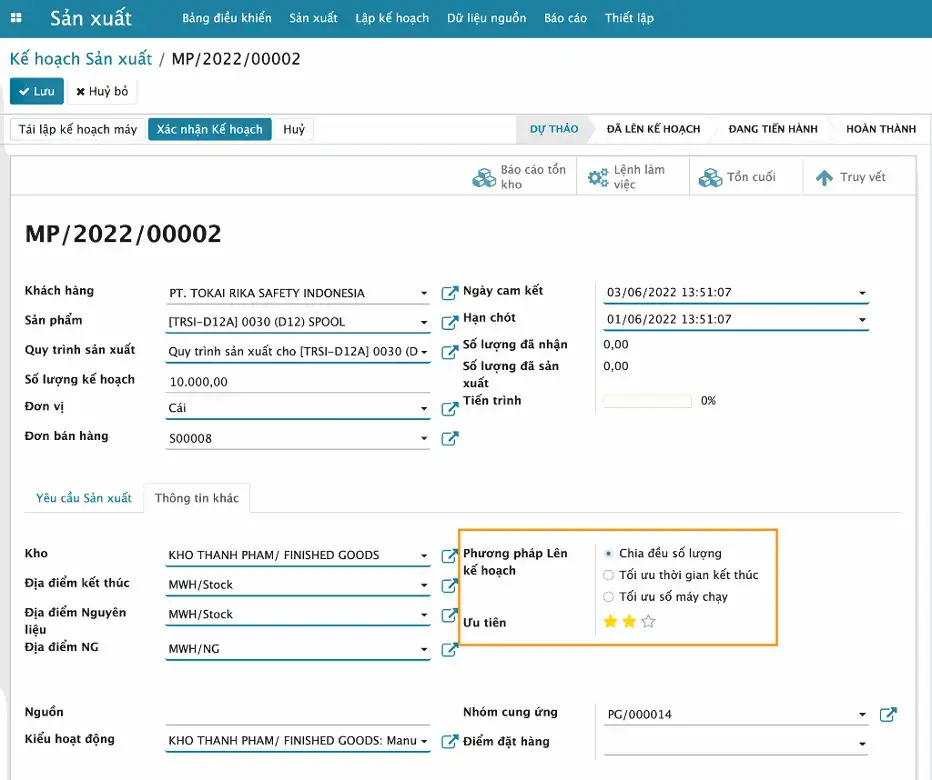

Automatically calculate and forecast production resources.

(Above image: The system automatically calculates production resources)

Based on the production capacity of each machine, each process stage for each product, and the available work orders, the MES software automatically optimizes calculations and issues work orders to each machine.

Alert delays in progress during the planning stage before production begins.

- Equal distribution of quantity

- Optimize completion time

- Optimize the number of machines in operation

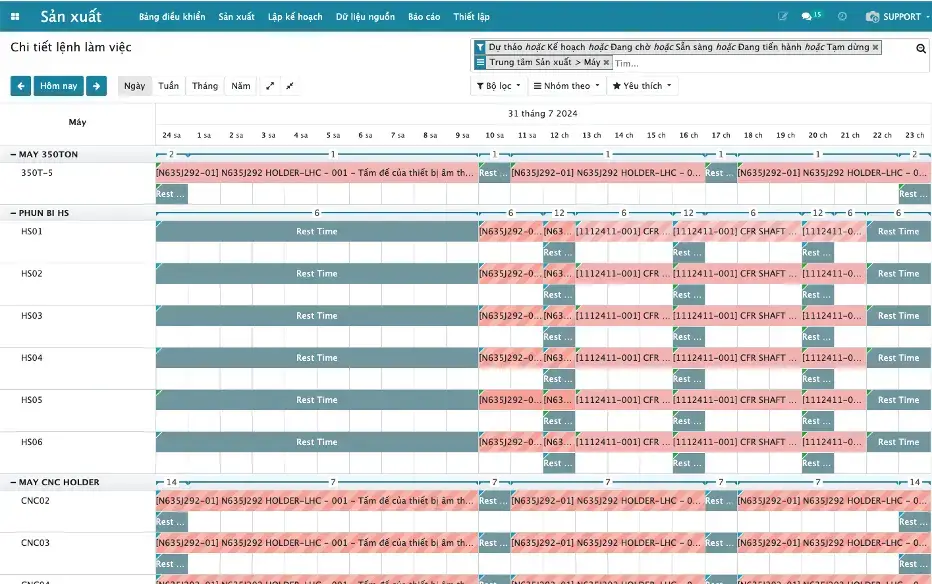

The work schedule of each machine.

(Above image: The work orders are automatically calculated for each machine, accurate to the minute, including rest time calculations.)

The machine management feature of the production management software automatically generates the work schedule for each machine and synchronizes it with the work schedules of other machines.

The manager of each machine can view the work orders assigned to their machine, arranged visually according to their status.

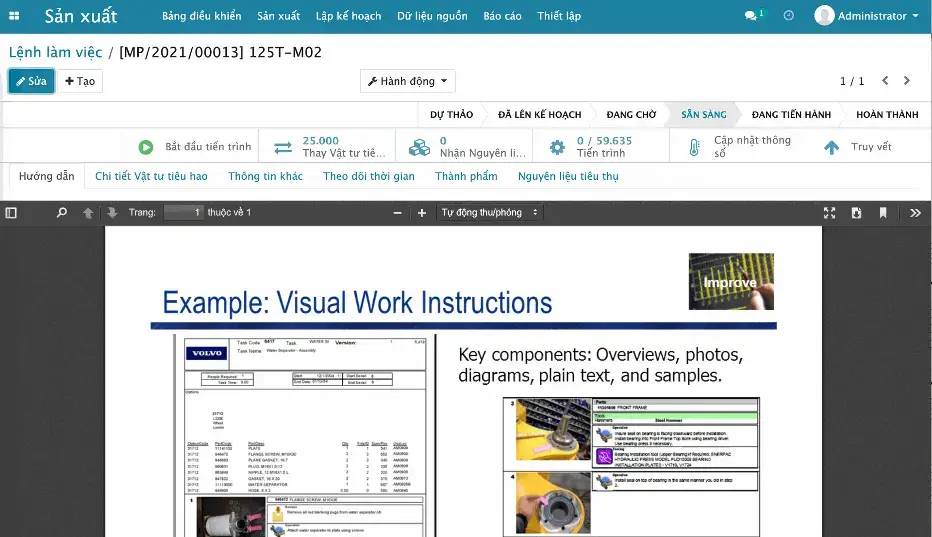

Instructions for operations at each process stage.

(Above image: Instructions for operations at each process stage.)

The OneMRP production management system supports the use of display screens for monitoring at each process stage. Users can:

- – View operation instructions for each process stage

- – Record activities such as receiving materials, tracking production progress, updating machine parameters, and transferring materials to the next stage

- – View all information related to work orders

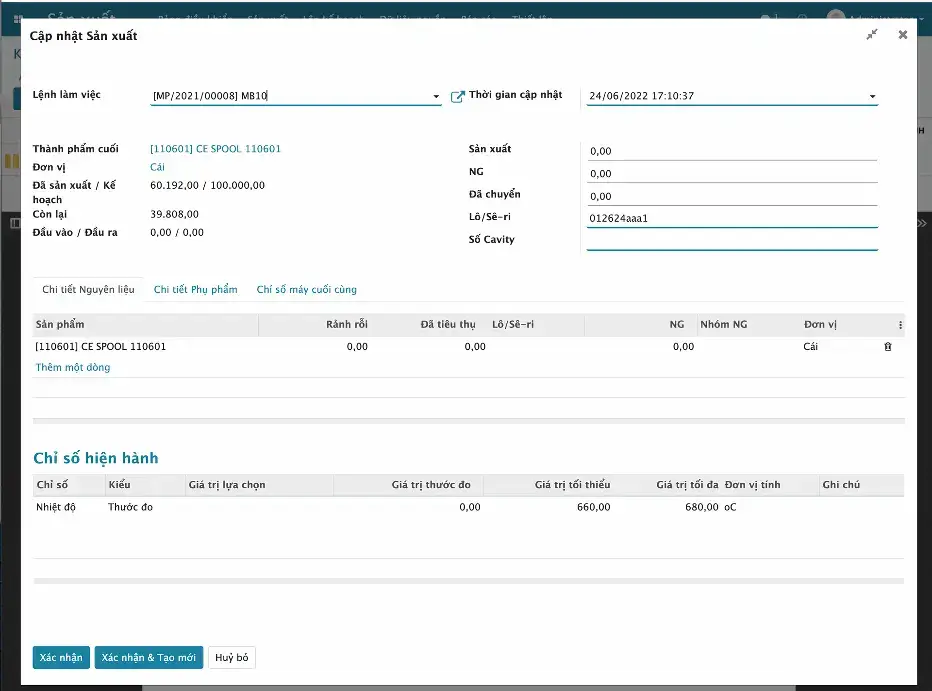

Update the production progress

(Above image: The system automatically updates production progress.)

The MES production system (AdoMES) allows for real-time production progress updates directly at each machine through a touch screen.

- Update the quantity produced

- Update the quantity of defective items by defect type

- Update semi-finished goods and finished products transferred to the next process stage

- Update material consumption

- Update machine metrics

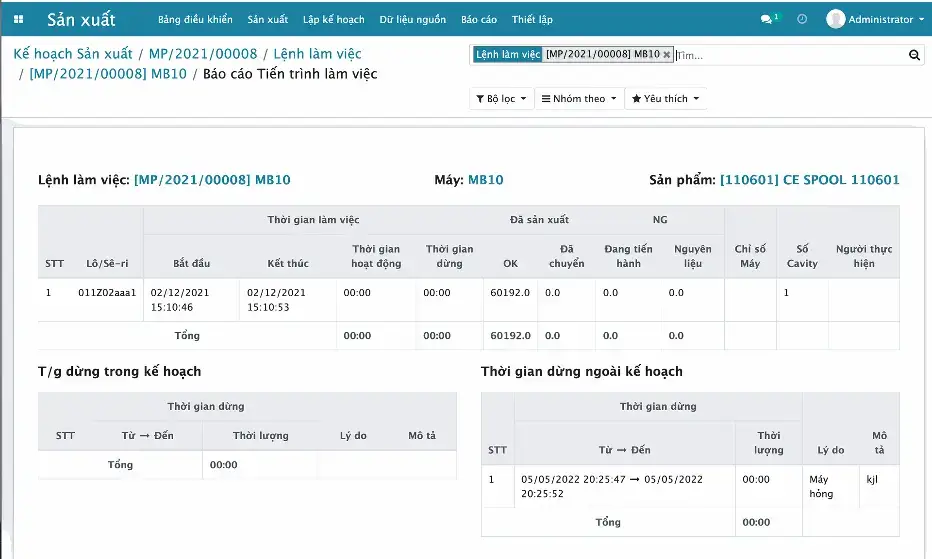

Production report

(Above image: Easily export various production reports.)

The MES production management and operation system offers a variety of reports that allow for analysis from multiple perspectives.

- Inventory report at each process stage by production order

- Dynamic NG (defective) report allowing multi-dimensional analysis

- Detailed traceability report

- Detailed production report for a specific production order

- Overall production report for the entire factory

- Production cost calculation report

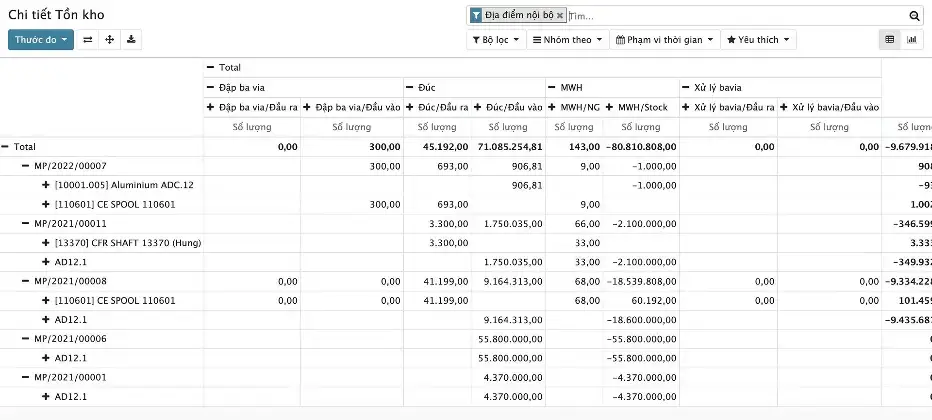

Inventory management at each process stage

(Above image: The system manages inventory in detail at each process stage.)

The MES production management and operation system allows for detailed inventory management at each process stage:

- Manage inventory of raw materials, semi-finished goods, and finished products before and after each process stage

- Manage the delivery and receipt of raw materials, semi-finished goods, and finished products from one process stage to the next

- Manage defective products

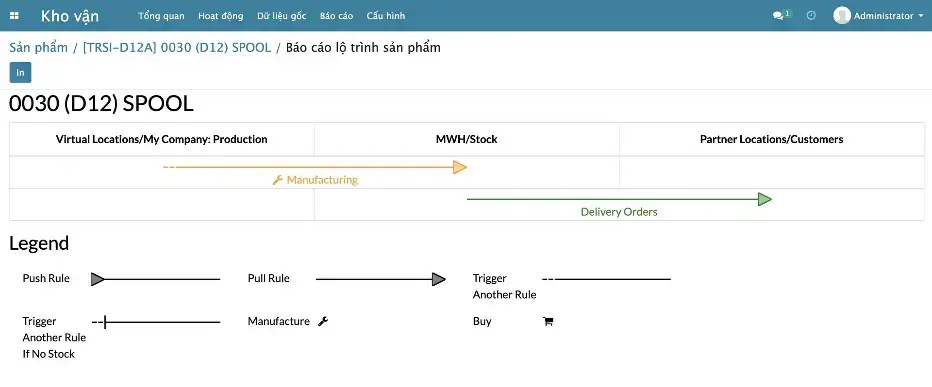

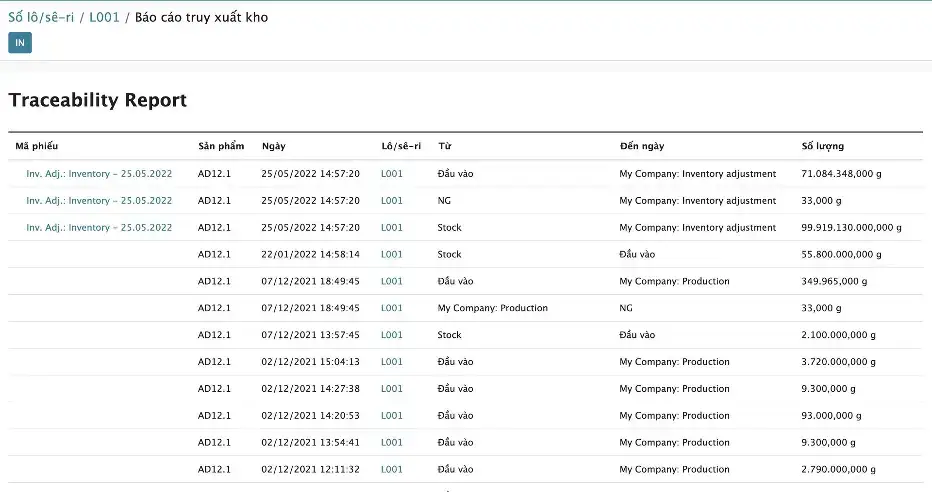

Traceability

(Above image: The system helps trace the origin of raw materials and goods.)

The MES production management and operation system allows for tracking all changes in inventory, from purchasing to receiving goods, to sales orders, and the material flow within each production order.

Track serial numbers or batch numbers from anywhere in your supply chain.

Manage scrap (NG) items

(Details: The system allows for managing scrap (NG) items at each process stage)

The MES production management and operation system allows for easy management of scrap items at each production stage. It provides reports on scrap statistics by process stage, time, machinery and equipment, classification, and cause.

Corrective and preventive actions to minimize NG (defective items).

Track and analyze NG (defective items) over time.

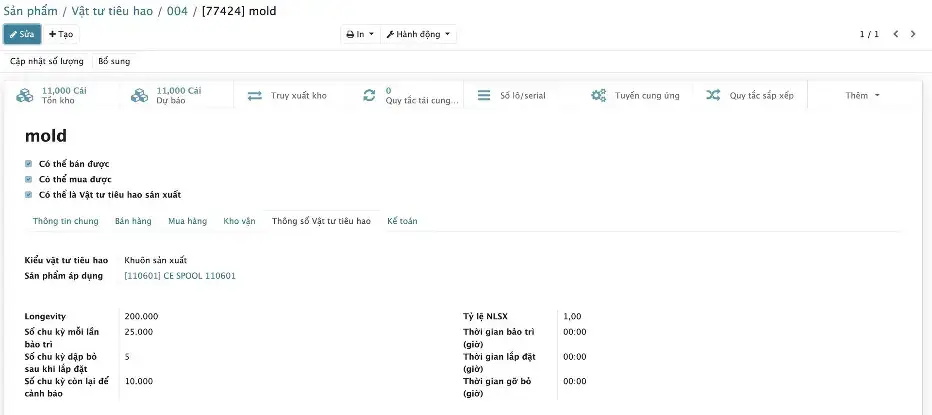

Manage consumable materials

(Above image: The system helps manage consumable materials)

Consumable materials are materials involved in the production process that are used up but are not part of the raw material components. For example, molds in the casting process, cutting blades in the cutting process, etc.

Consumable materials can be tracked in detail by serial number. For example, each mold in the casting process can be monitored individually for the number of cycles used, remaining lifespan, number of maintenance sessions performed, and the predicted time for the next maintenance.

Track the number of cycles that consumable materials have been used.

Automatically schedule and plan maintenance for consumable materials, with maintenance alerts when due.

Automatically schedule the replacement of consumable materials when they reach the end of their lifespan and provide alerts for replacement when the time arrives.

Calculate production cost

The MES production management and operation system allows for accurate calculation of production costs, including direct costs and the allocation of monthly overhead costs. It automatically calculates the cost of goods sold using periodic averaging, including complex allocations.

- Accurately estimate direct production costs, including material costs, machine costs, and labor costs, immediately after setting up the BOM (Bill of Materials) and production processes.

- Accurately report actual production costs for each production order based on real-time consumption, actual material usage, considering the quantity of NG (defective items), and actual labor costs.

The Odoo ERP systems developed by AdoERP are being used by over 50,000 satisfied users

Frequently asked questions related to MES + ERP production management software.

What is production management software?

Production management software is a tool that helps businesses monitor, manage, and optimize production processes. It offers functions such as production planning, material management, progress tracking, and product quality control.

What are the benefits of using production management software?

Using production management software enhances operational efficiency, reduces costs, improves product quality, and provides a clear overview of the entire production process. It helps businesses make smart and timely decisions.

What is a MES and why is it important?

A Manufacturing Execution System (MES) is a software solution used to monitor and manage production activities in real-time. MES helps improve production efficiency, reduce downtime, and optimize material management.

At AdoERP, we have created AdoMES, a comprehensive production management solution that combines MES and ERP, running together within the Odoo ecosystem. It is fully integrated with other Odoo functions such as Sales, Inventory, Purchasing, Financial Accounting, Human Resources, and MES, helping to create a complete workflow throughout the entire operational chain of the business.

What makes ERP production management software different from regular production management software?

ERP production management software (Enterprise Resource Planning) not only manages production but also integrates with other functions such as finance, human resources, and inventory management. This helps synchronize information and improve overall workflows.

What are the key features of AdoMES production management software?

AdoMES production management software is a specialized MES production operating system that works within the Odoo ERP ecosystem. It provides features for managing production processes, production planning, progress tracking, material management, and quality control, synchronized with other Odoo functions such as finance, sales, purchasing, inventory, human resources, and more.

How to implement production management software effectively?

To implement production management software effectively, you need to create a detailed plan, clearly define the business requirements, and ensure proper training for employees on how to use the software. Sometimes, collaborating with a service provider for software implementation is a good solution.

Contact AdoERP to see a live demo of the AdoMES solution and evaluate it for yourself.